Ukubumba

Sine-punching-slot slot, i-punching ye-slot, i-punching, kunye nesantya esiphezulu esibonakalayo esihambelana ne-Polds ukuze sihlangabezane neemfuno zemoto ezahlukeneyo. Malunga ne-90% yethuIzikolo zeZithuthi zinikezelwe ngokwezixhobo. Ngexesha loyilo lwe-GOLD, abaqulunqi bethu abaziingcali ziya kwenza ukuba amanye amacebiso awongezelelekileyo kubathengi abafezekisayo.

Iisampulu zenza

Singafezekisa ubungakanani obahlukeneyo kunye netekhnoloji yemfuno yesampulu yemoto.

A

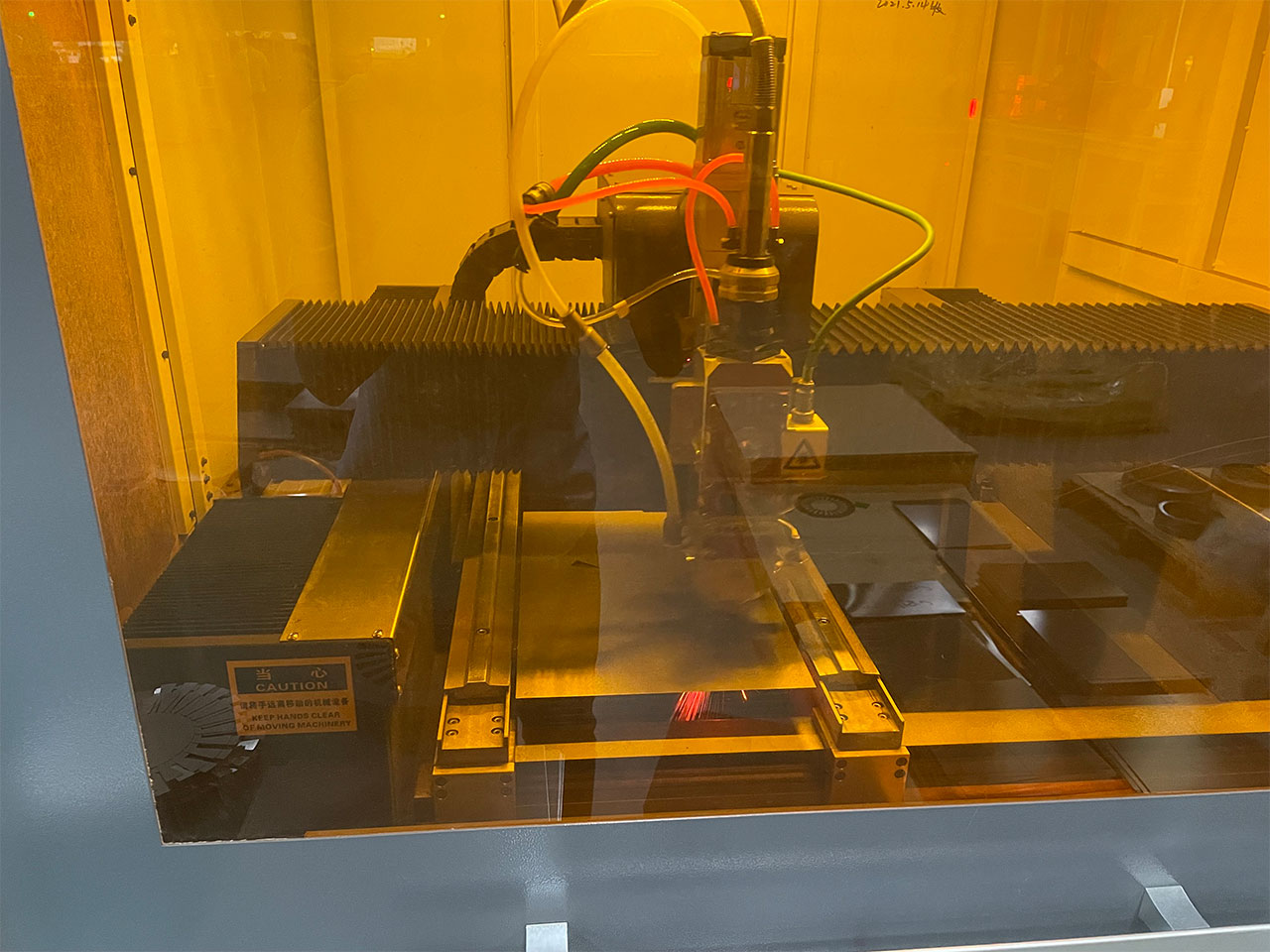

Ukusika i-laser

C

Isantya esiphezulu somcingo

B

Isantya esiphakathi esinqunweyo

D

I-Wire yeKhaya eliphantsi (Sasingenisa umatshini we-sebib brand ukusuka eJapan)

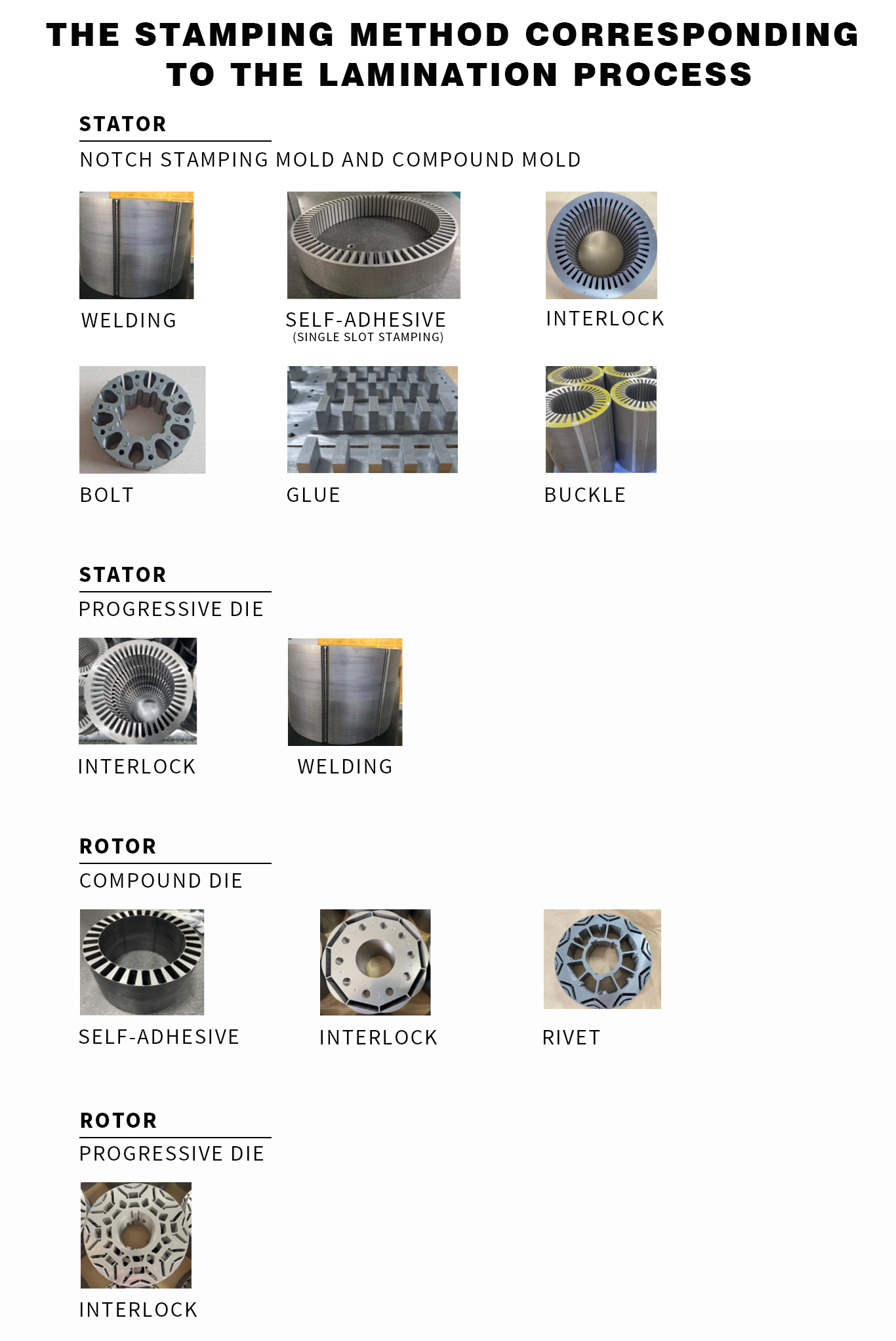

Isitampu

Sineentlobo ezahlukeneyo zoomatshini bokushicilela ukuze bahlangabezane neemfuno zakho zokuthenga ezahlukeneyo.

I-slot enye slot

Ucinezelo: I-10T-16T

I-timplate ecekeceke

Oomatshini bokushicilela: 40t-550T

Inkqubela phambili(Isantya esiphezulu)Isitampu

Ucinezelo: I-630t, i-550t, i-315t (Schuler),I-300t (AIFA),I-160t, i-120t, I-80t (Nidec)

Iworkshop yetampu kunye neNzuzo

↓

I-A.Igcle i-Advaler Izixhobo ze-Schus eziphambili kunye neTekhnoloji evela eJamanikunye ne-AIFA, UNidec eJapan,Oko masizivumeleIzikolo zeZithuthiishishini elikhokelayo lever ngoku.

I-B.achieve ye-BCHCH yemveliso ye-0.1mm yentsimbi yentsimbi yentsimbi kunye ne-0.03mm ubukhulu bezinto ezibonakalayo.

C. I-CYTATRE SOTE STORT ingenzi isitampu se-od2000mm max.

I-slot enye slot

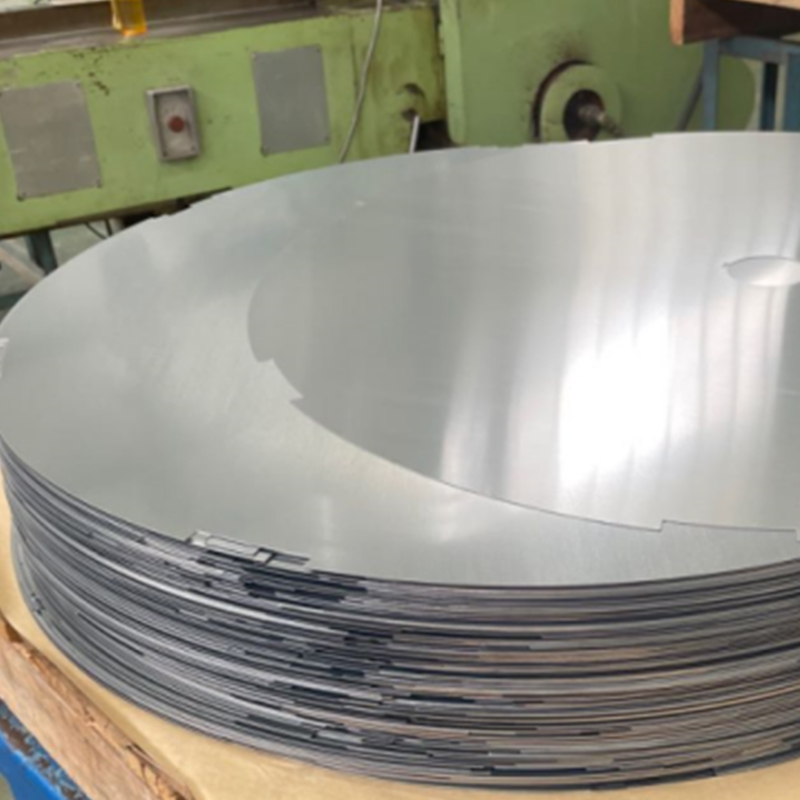

Isixhobo

Sika iphepha lentsimbi yeSilicon ukuba libe yisayizi, kwaye isiqwenga ngasinye siya kuba ngasinye sifakwe kwimo efunekayo. I-Sloat enye yeSlot yeyona ndlela ifanelekileyo ye-stactores elona ziko lezitetori ezinobubanzi bezinto ezinkulu zangaphandle kunye nenani elikhulu leesampulu.

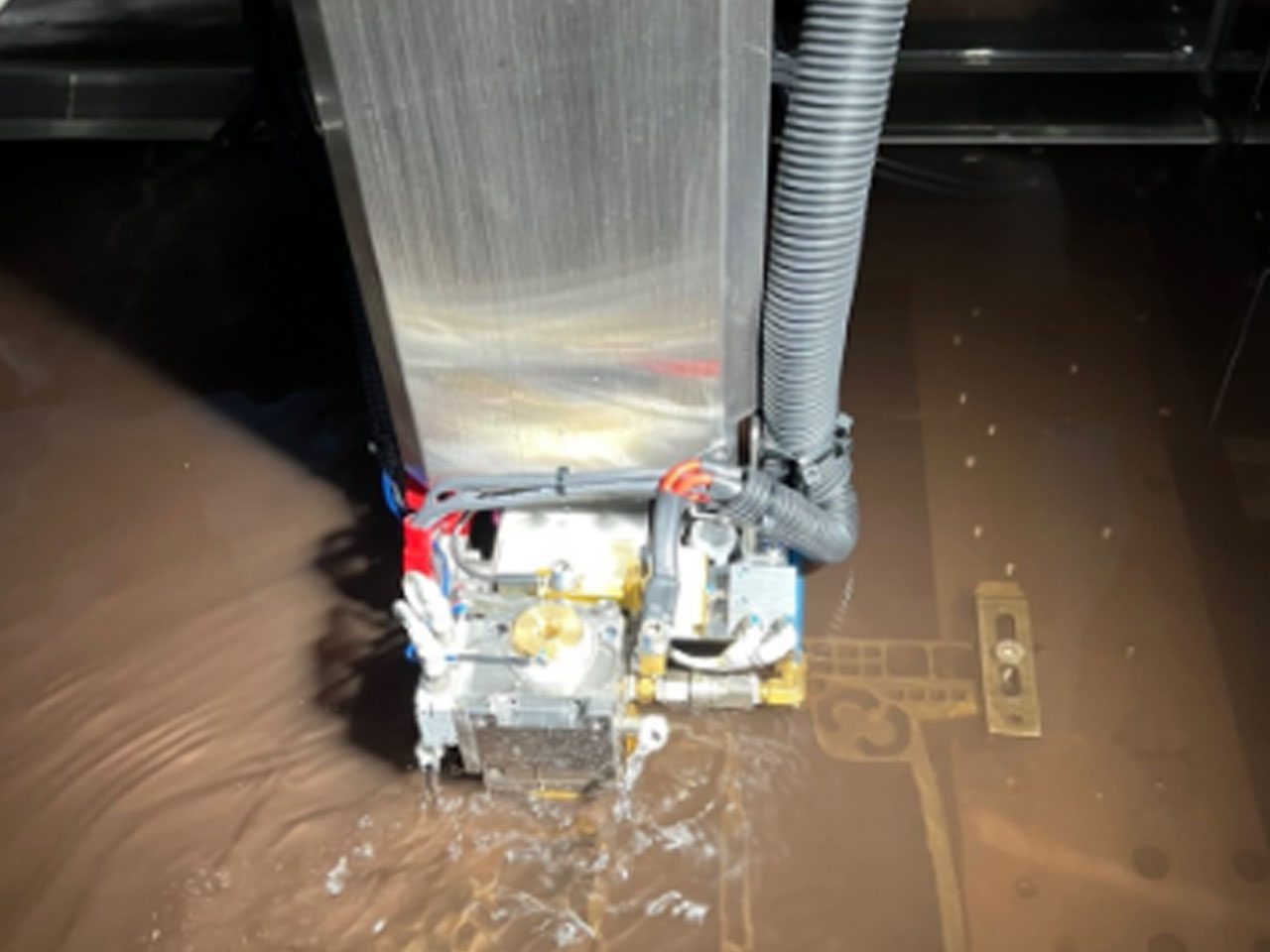

I-timplate ecekeceke

Isixhobo: I-Dieweund Die

Thenga umtya wentsimbi ehambelana ne-silicon ngokobungakanani bemveliso efunekayo, tshintshela umxholo wokushicilela wesitampu, emva koko uqumbisa izifo, zombini ezitatori. Kukho iindlela ezimbini zokutyisa, enye kukusebenzisa i-wafed edutyulwe lilinye i-lamotion, elingenayo, kodwa lingasindisa iindleko zempahla; Enye iqhubeka ukutya okuqhubekayo kwemithombo, ngokusebenza kakuhle.Siyijonga imeko ye-wafet yesitokhwe xa umthengi ebeka iodolo, emva koko wabala eyona mali ilungileyo yokwenza isivumelwano semoto kunye ne-rotor. Ukongeza, inkampani yethu inayo ilungelo elilodwa lomenzi welungelo lokuziqhelanisa ngokulinganayo, inciphisa iindleko zokungqinisisa izithuthi kwinqanaba lokuqala le-Bhatch eqhubekayo.

Inkqubela phambili

Isixhobo: Ukufa okuqhubela phambili

Olu hlobo lokubumba lukwabizwa ngokuba sisitampu esiphezulu. Ukwahluka kwi-conbund yokubumba, kunokusebenzisa kuphela ububanzi bezinto ezifanelekileyo zokutya, ukugqiba isitampu kunye nokuziqhelanisa nokuziqhelanisa ngokuthe ngqo ukwenza i-stator kunye ne-rotor stack.

Zimbini iintlobo zokuzifakelwa. Inqaku elinye lendawo yokuziqhelanisa nenqanaba elincinci lesantya esincinci sezigidi zeemoto, ezineemfuno eziphezulu zobugcisa. Izitavu azidingi ukuba zicinezelwe kabini kwi-fict-fictions.The enye yindawo yokuzila enguxande, efuna uxinzelelo lwesibini ukuqinisekisa ukuba uqinile.

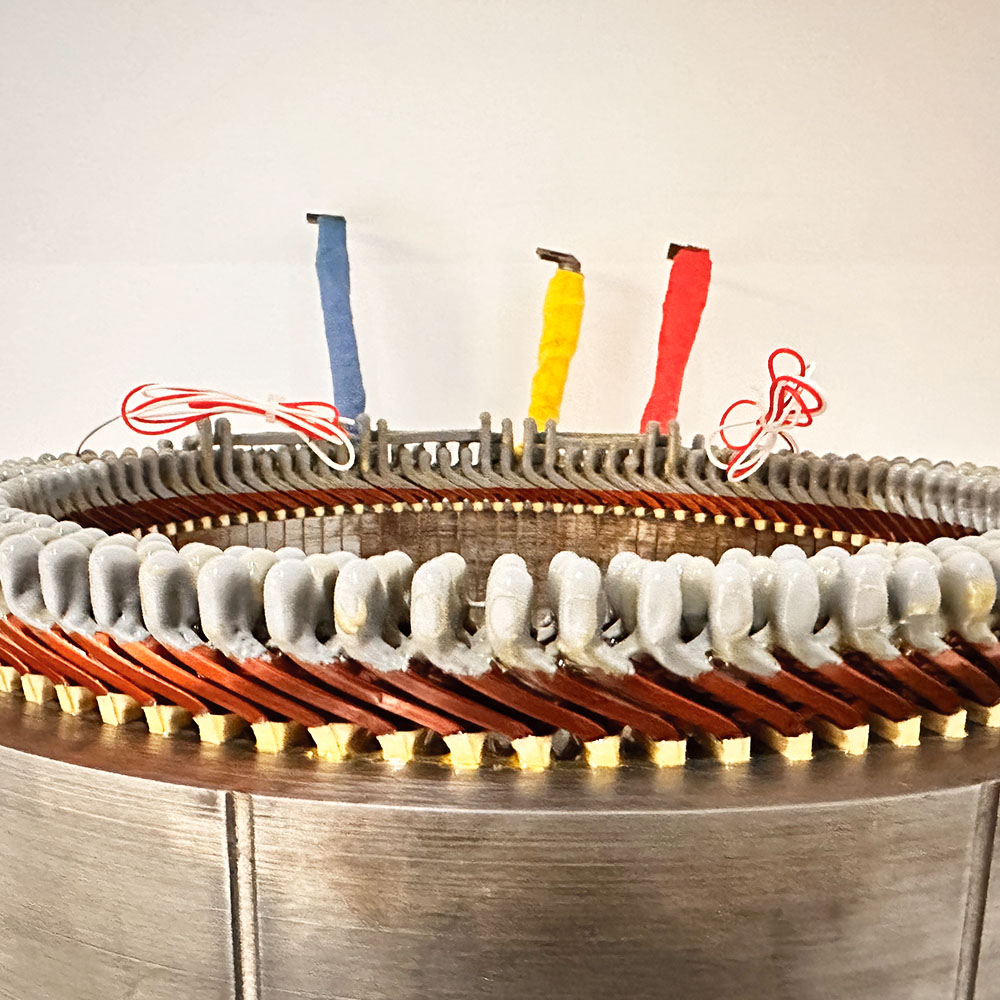

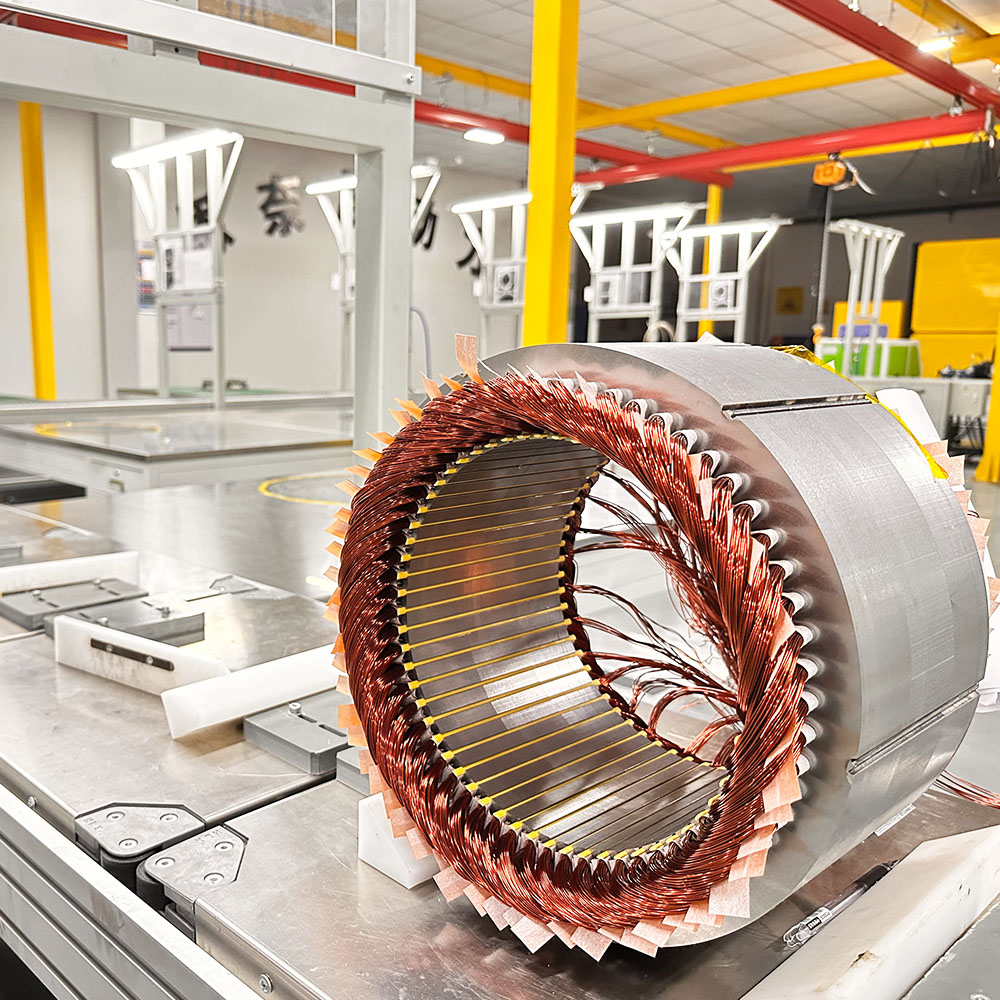

INdibano ye-Star

Sinikezela ngocingo olujikelezileyo kwaye sinamagqabi amancinci, omabini amancinci kwindawo yesampulu kunye neebatch ezinkulu kwinqanaba le-15-500mm, i-2-5mm, i-2-8 yeendawo zokuvelisa azingqinelani. Isiseko se-5-50 seeseti / usuku.

Ukuqaphela

Isilisa siya kufakwa kwindawo yokuqengqeleka, singene, sine-Wilding, ukuzibulala, i-Blue, i-Blue, i-Woot, isetyenzisiwe kakhulu.

Rivet

I-Rivet Starks isetyenziselwa i-rotor, kukho intloko yentloko kunye ne-rivet yeflethi.

Ilding

I-Welding Stark isetyenziselwa ukwahlula izitayile, kukho i-larer welding kunye ne-tig welding.

Iglue

Ipeyinti kwiglue kuzo zonke izifo ezikhululekileyo kwaye zibambelele kunye.

Nxibelelana

Yenza amanqaku amanqaku ngexesha lokuhamba ngesitampu, ukulelisa izithuthi kuya kubhangiswa kwizindlu zazo zezinto. I-inclock inokuba yi-oxang okanye isetyhula. Ukuqhubela phambili kwesitampu yonke usebenzisa inkqubo ye-interlock ukugcina i-stator kunye ne-rotor stack indleko kunye nexesha.

Ukuzibulala

Izixhobo: B35A300-Z / B5A400-Z / Z

Izinto ezinomxholo zibambisana kumphezulu wayo, ziya kunyibilika kwaye ziqhoboshele yonke i-rotor enye kunye ne-stactolotion ngesandla kunye ngexesha lokufudumeza. Ukuzincama kuya kwenza iimveliso zikhazimla kwaye ziqinile ngakumbi.

I-bolt

I-BOLT isetyenziselwa amaleatoritions e-stator ene-diameter enkulu yangaphandle.

Buckle

I-Buckle isetyenziselwa ukusetyenziselwa i-stator lamonition, kukho i-buckes ethe tye okanye i-skew.

Uhlolo

Izixhobo zethu zokuvavanya zibandakanya iprojektha, zilungelelanisa ezintathu, zonqula imitha, ilahleko ye-iron ilahleko, i-tester, i-tester, kunye ne-HMM inozimiso, i-hexagon, kunye ne-hentel brands.

Ukuhlolwa kwahlulelene kwinqaku lokuqala, ukuzihlola, ukuhlolwa kwepatroli kunye nokuhlolwa kokugqibela. Nokuba yeyiphi na indlela yokuhamba kwesitampu, iziqwenga ezimbalwa zokuqala ze-stator kunye neeseti zokuqala ze-stator kunye ne-rotor stacks ezinokuthunyelwa kwigumbi lokuhlola, kwaye imveliso eninzi inokwenziwa kuphela emva kokuba kuvavanywa kuphela.

Ukupakisha

Ngokweemfuno zabathengi, amaziko kunye neentambo zipakishwe ngekhephu zentsimbi, iibhokisi zeplastiki, iibhokisi zeplywood, njl. Njl.

Xa i-pronger yemoto efanelekileyo okanye i-stator kunye ne-rotor sticks igqityiwe, siyahlulahlula ngesiponji kwaye sipakishe kwityala elingezonziwe ngamaplanga ukuze sizinikele ngaphandle.